NEWS & INSIGHT

NEWS & INSIGHT

Discover the latest news and insight pieces from our diverse team of experts.

February 5, 2026

American Golf is acquired by an investment Grou...

Peter Jones and his investment Group has acquired American Golf, the UK’s largest golf retailer, from private equity investors,...

January 6, 2026

ENACT COMPLETES TWO ACQUISITIONS OVER THE CHRIS...

The Enact Fund, managed by private equity firm Endless, is delighted to announce the completion of two acquisitions over the Christmas pe...

December 17, 2025

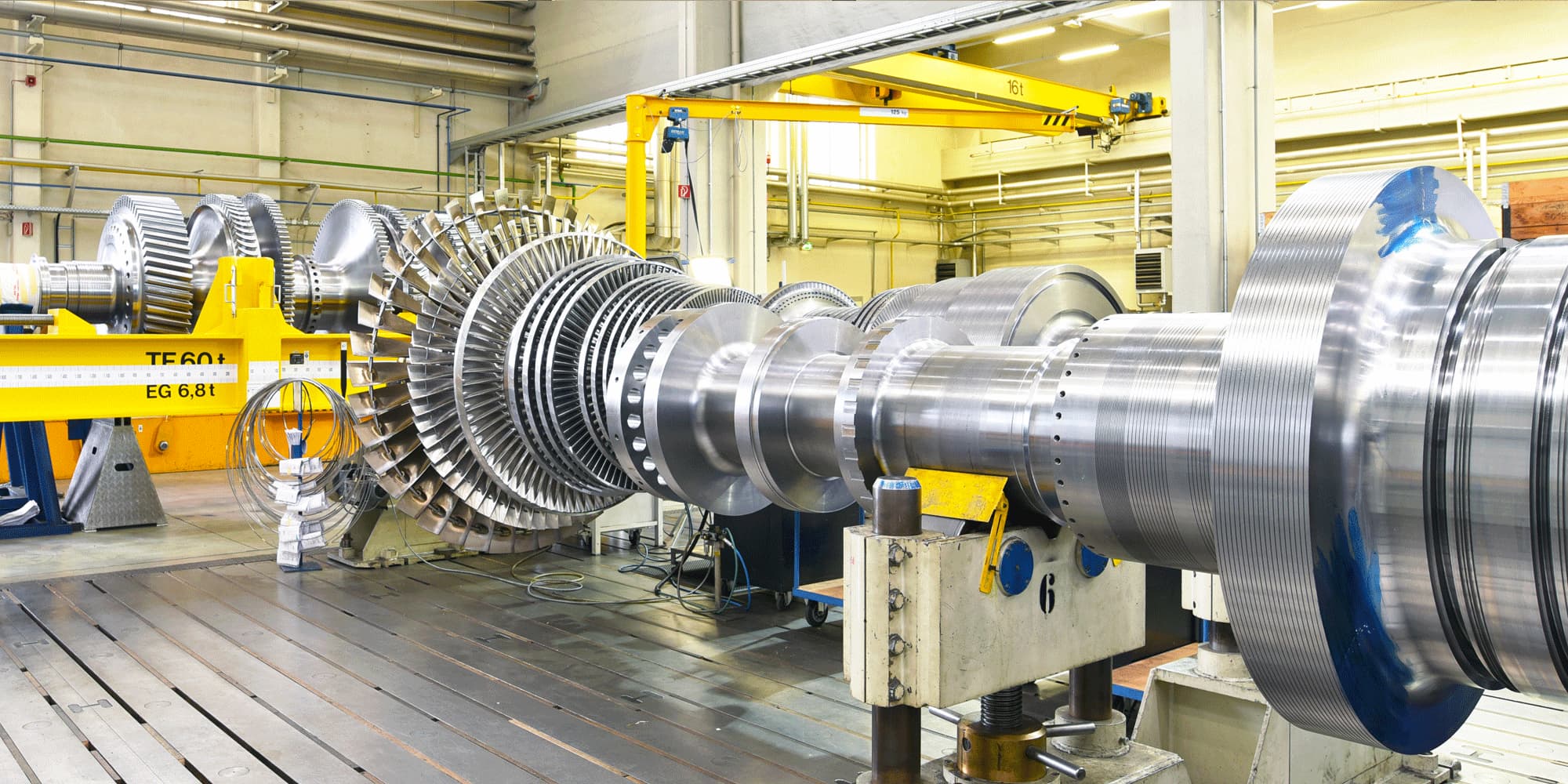

ENACT SELLS GREENRAY TURBINE SOLUTIONS TO FLOWS...

Yorkshire-based SME investor Enact, which is managed by private equity firm Endless, has today confirmed the sale of Greenray Turbine Sol...

December 11, 2025

WE’RE DELIGHTED TO SHARE THAT ECOBAT BATT...

As Europe’s largest independent battery distributor, Veloris, the battery partner evoking velocity and motion, captures the business’s ab...

December 2, 2025

Endless celebrates 20th anniversary with stella...

As the Leeds headquartered firm celebrates its 20th anniversary, Endless remains committed to supporting the development of great Yorkshi...

December 2, 2025

A Remarkable Evening for Endless at the Yorkshi...

We are proud to announce that Endless achieved outstanding success at this year’s Yorkshire Dealmakers Awards, winning three prestig...

November 11, 2025

Growing Your Family Business Through Acquisition

Business growth through acquisition is an increasingly popular strategy across a wide range of sectors in the UK. It offers companies the...

October 28, 2025

Enact completes sale of Realise Training Group ...

Yorkshire-based SME investor Enact, which is managed by private equity firm Endless, has today confirmed the sale of Realise Training Gro...

October 23, 2025

Endless Investment Team Crowned TMA Turnaround ...

We’re incredibly proud to share that Endless Investment Manager Rachel Holloway and her team have won the TMA Turnaround Competitio...